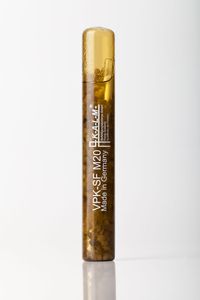

Chemical anchor capsule VPK-SF styrene free, approval ETA-08/0231

Approved for anchoring in non-cracked concrete in connection with K-A-L-M anchor rods of the designs: zinc-plated ASK, hot-dip galvanized ASK-F, stainless steel A4 ASK-E and stainless steel highly corrosion-resistant 1.4529 ASK-H.

How it works: The composite anchor cartridge consists of a glass tube that is made up of a resin mixture, coarse quartz sand and an inner tube filled with hardener powder. The anchor rod is inserted into the borehole by hammering and rotating by means of a drilling device. During this process, the glass tubes are destroyed. The quartz sand grinds the glass splinters and mixes the resin with the hardener homogeneously. The mixture fills the space between the fastener and the borehole wall. After the mixture has hardened, the anchor rod can be loaded with the specified load.

Areas of application: For anchoring heavy loads in non-cracked concrete, e.g. high shelves, guardrails, noise barriers, facades, machines, railings, etc. in dry, damp and aggressively damp environments such as chlorine or salt water.

Properties: Chemical anchors are particularly suitable for applying high load values with small edge and center distances, as they anchor without expansion pressure. They can be used in dry and damp subsoil, as well as cost-effective and efficient for side-by-side assemblies.

Product | Drill-Ø | Drill depth | Art.-No. | Qty |

[mm] | [mm] | |||

VPK-SF M8 | 10 | 80 | 123 08 000 | 10/200 |

VPK-SF M10 | 12 | 90 | 123 10 000 | 10/200 |

VPK-SF M12 | 14 | 110 | 123 12 000 | 10/200 |

VPK-SF M14* | 16 | 120 | 121 14 000 | 10/200 |

VPK-SF M16 | 18 | 125 | 123 16 000 | 10/200 |

VPK-SF M20 | 25 | 170 | 123 20 000 | 5/50 |

VPK-SF M24 | 28 | 210 | 123 24 000 | 5/50 |

VPK-SF M30* | 35 | 280 | 121 30 000 | 5/25 |

*not part of the approval |

Hammer-in capsule HPK

The simple solution for difficult fastening tasks.

How it works: The hammer cartridge consists of an inner tube filled with a resin mixture and surrounded by hardener. The small glass tubes are destroyed by hammering in the reinforcing steel, whereby the two components are mixed and fill the space between the reinforcing steel and the borehole wall. After the mixture has hardened, the reinforcing steel bars can be loaded with the specified load.

Areas of application: Mainly in reinforced concrete construction, e.g. for fastening profiled reinforcing steel.

Properties: - It is set by hammering it in, no special tools are required - Exact dosage of the resin system - Anchoring without expansion pressure thanks to the bond between the fastening element and the borehole wall.

Product | Rebar | Threaded rod | Art.-No. | Qty | ||

Drill-Ø | Drill depth | Drill-Ø | Drill depth | |||

[mm] | [mm] 1/2 | [mm] | [mm] | |||

HPK 10 | 13 | 90/180 | 12 | 90 | 101 10 000 | 10/200 |

HPK 12 | 15 | 110/220 | 14 | 110 | 101 12 000 | 10/200 |

HPK 16 | 20 | 140/280 | 18 | 125 | 101 16 000 | 10/200 |

HPK 20 | 25 | 180/360 | 24 | 170 | 101 20 000 | 5/50 |

HPK 24 | 30 | 210/420 | 28 | 210 | 101 24 000 | 5/50 |

Chemical mortar cartridge VMK-SF ETA-04/0072 & VMK-SFZ ETA-15/0858+ETA-16/0808, Styrene free

VMK-SF ETA-04/0072: Approved for anchoring in non-cracked concrete.

VMK-SFZ ETA-15/0858 & ETA-16/0808: Approved for anchoring in cracked and non-cracked concrete and masonry.

Mode of operation: The components, consisting of resin and hardener mixture, are located in two separately arranged chambers. Using a dispensing tool, the two components are mixed in a screwed-on static mixer to form a highly stressable mortar mass, which is then pressed into the borehole for fastening.

Areas of application: fastening of e.g. steps, monuments, fountains, window grilles and machines. For grouting in connection elements such as profiles, anchor rods, grids, railings, facades. The styrene-free composite mortar cartridges can also be used in damp and aggressively damp environments, such as chlorine or salt water.

Properties: Composite mortars are characterized by their easy handling and guarantee a fastening without expansion pressure with a high load-bearing capacity. The possible uses of the composite mortars are varied, so there are a large number of possible applications for industrial and private use. The coordinated two-component composite mortar systems enable precise and simple dosing of the mortar mass.

Product | Art.-No. | Qty |

VMK 150 | 20115000 | 10 |

VMK 345 | 20134000 | 10 |

VMK 380 | 20138000 | 12 |

VMK 825 | 20182000 | 5 |

VMK-SF 150* | 20215000 | 10 |

VMK-SF 280* | 20228000 | 10 |

VMK-SF 345* | 20234000 | 10 |

VMK-SF 380* | 20238000 | 12 |

VMK-SF 825* | 20282000 | 5 |

VMK-SF 280 - Winter** | 20328000 | 10 |

VMK-SF 345 - Winter** | 20334000 | 10 |

VMK-SF 380 - Winter** | 20338000 | 12 |

VMK-SFZ 150*** | 20615000 | 10 |

VMK-SFZ 280*** | 20628000 | 10 |

VMK-SFZ 345*** | 20634000 | 10 |

VMK-SFZ 380*** | 20638000 | 12 |

VMK-SFZ 825*** | 20682000 | 5 |

All catridges incl. 1 mixing nozzle | ||

* Styrene free with ETA-04/0072 approval | ||

** Styrene free without approval | ||

***Styrene free with ETA-15/0858 & ETA-16/0808 approval (for cracked and non-cracked concrete and masonry) |

Chemical mortar box VBK

Content:

VBK 345 + VBK-SF 280 + VBK-SF 345 + VBK-SFZ 280 + VBK-SFZ 345:

20 Cartridge & 40 Mixing nozzle

VKK 28:

15 Cartridge, 30 Mixing nozzle

Chemical mortar set VMK 150

Content:

1 cartridge VMK 150 incl. adapter,

4 sleeves 15x85mm,

1 mixing nozzle,

4 threaded rods M10x100 mm

Chemical mortar case VKK

Content:

1 suitable dispensing tool, 1 blowpump, 1 brush FBK 12 and 1 brush FBK 18,

10 sleeves 12x50 and 10 sleeves 15x85,

VKK 34 + VKK 38: 3 cartridge, 6 mixing nozzles

VKK 28: 4 cartridge, 8 mixing nozzles

VKK 15: 6 cartridge, 10 mixing nozzles, 1 adapter

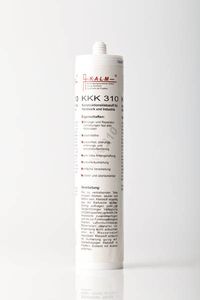

Construction adhesive KKK

The construction adhesive KKK 310 is a D4 adhesive according to DIN EN 204, tested by ift-Rosenheim, test report no. 505 24562/1, heat-resistant according to WATT 91.

Processing: The substrates to be bonded must be free of dust, grease and oil, as well as solid and stable. If necessary, sand down beforehand. Apply construction adhesive KKK 310 from the cartridge in a bead-like manner, distribute with a notched trowel when bonding surfaces. One-sided adhesive application. In the case of non-absorbent substrates, it is recommended to apply adhesive on both sides. Put the parts together and, if necessary, fix them until they are ready for assembly or hardening. When bonding wood, the residual moisture in the wood should be approx. 8 - 10%. The construction adhesive KKK 310 hardens by means of moisture with gap-filling bonds approx. 2 - 3 mm per day. The hardening process is accelerated by adding water mist and higher temperatures.

Areas of application: Structural bonding of wood-based materials, combination bonding with metals, plastics, concrete, brick, stone, marble and natural stone, styrofoam, rigid foam, plasterboard, decorative panels, insulating materials, sandwich panels, wall cladding. Gluing in wooden window construction, aluminum window corner brackets, window sills, house door panels, stairs and installation panels.

Properties: - Assembly and repair bonding of almost all materials - Solvent-free - Waterproof, resistant to aging, weathering and temperature - Very high initial adhesion - Fast curing - Easy processing - Can be sanded and painted over - Use of conventional dispensing guns - For indoor and outdoor use

Self leveling NMK

Mode of action: The components consisting of hardener and a resin mixture are in two separate containers. If the two are mixed in the container, a flow mortar is created that can withstand high loads.

Areas of application: fastening of e.g .: steps, monuments, fountains, street signs and machines. Mortar-in of connection elements in the subsurface, such as: reinforcing iron, profiles, anchor rods, grids, etc.

Properties: The leveling compound is characterized by its easy handling and anchoring in the ground without expansion pressure. There are many possible uses in the industrial as well as in the private sector.